As an experimental Su-27 variant, the Su-27LL-PS tested advanced 2D thrust vectoring for enhanced maneuverability, providing critical insights into supermaneuverable flight dynamics, material innovation and jet nozzle engineering.

The Su-27LL-PS was an experimental variant of the Su-27 fighter aircraft designed to test advanced thrust vectoring technologies. It featured a two-dimensional thrust-vectoring nozzle system, enabling the aircraft to control exhaust direction for improved maneuverability. This made it a key platform for studying supermaneuvrability and aerodynamic behavior at high angles of attack.

Leading up to Su-27LL-PS Development

The Sukhoi Su-27 Flanker, a Soviet fourth generation twin-engine air superiority fighter, first took to the skies on May 20, 1977. The aircraft demonstrated exceptional performance, including high maneuverability, speed and range, and was designed to counter sophisticated American fighters like the F-14 and F-15. The original Flankers were powered by twin Saturn-Lyulka AL-31F afterburning turbofans, which were very reliable by Soviet standards, but lacking the thrust vectoring. The aircraft quickly proved itself, and by the late 1970s and early 1980s the Flanker had become a symbol of Soviet airpower.

As the technological arms race intensified in the 1980s, supermaneuvrability became a key focus in Soviet air doctrine. Driven by Western advancements like the U.S.’s X-31 experimental aircraft, and maneuverability issues during maneuvers with high angles of attack, a lot of research was conducted by Soviet engineers into thrust-vectoring engines that allowed the aircraft extreme agility.

The Flanker was the natural choice for experimentation on the subject due to its robust, proven design and aerodynamic excellence. Alongside the thrust-vectoring, Soviet engineers and scientists were also exploring innovative heat-resistant materials that could withstand the tremendous heat and stress associated with high-performance flight.

The Su-27LL-PS was in no way the first ‘modified’ Flanker; Sukhoi explored various Su-27 modifications such as avionics and aerodynamic enhancements, paving a way for more experimental variants. The Su-27LL-PS focused on 2D thrust vectoring and was part of a broader effort to retain a technological edge over NATO competitors, even as internal struggles within the Soviet Union were becoming more and more common.

Base Airframe and Modifications

The Su-27UB Flanker-C is the two-seat trainer variant of the Su-27, designed for training pilots while maintaining full combat functionality. Like its single-seat counterpart, the Su-27UB is equipped with powerful AL-31F turbofan engines, advanced avionics, and the capability to carry a wide array of air-to-air and air-to-ground munitions.

Despite the addition of a second seat for an instructor, the aircraft retains its long range and exceptional maneuverability, a result of its carefully engineered weight distribution and large wing area. This made it a versatile aircraft suitable for both training and operational combat roles, and also a perfect base model of the LL-PS. The particular airframe used for the program was Su-27UB Flanker-C coded 08 Blue, built in plant No. 39 at Irkutsk. It was converted to the special LL-PS configuration at production plant No. 129.

The most significant change from the standard Su-27UB was the addition of 2D thrust-vectoring nozzles, which replaced the standard exhaust system to allow directional control of engine thrust.

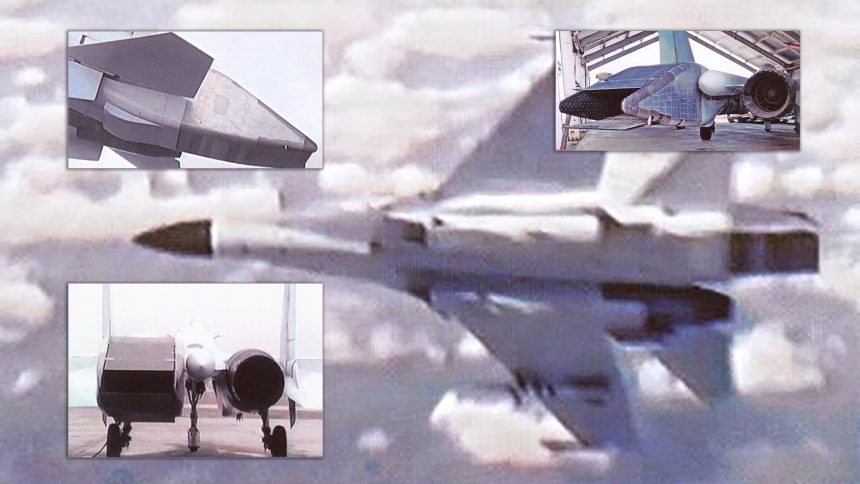

The aircraft featured two AL-31Fs with two different nozzle shapes. The nozzle for the left side engine of the Su-27LL-PS’ thrust-vectoring system was developed by NPO Motor and had two flap-like nozzles that can direct the exhaust gasses up and down at an angle of ±15°, much like the U.S. F-22A’s Pratt & Whitney F119 engines. The nozzle for the right-hand side engine, developed by NPO Saturn, held a conventional looking, circular engine nozzle.

The exhaust nozzles are the part of the engine where hot, compressed air is expelled from. Traditional fighter engines have variable geometry nozzles, meaning the outlet’s diameter can be controlled and the performance can be maximized across different throttle settings – when the throttle is powered up, diameter of the nozzle’s diameter decrease while the opposite happens when the throttle is powered down.

When the direction of the nozzles is adjusted up or down, the force pushes the tail of the aircraft in the opposite direction, augmenting the elevators and allowing the aircraft to point its nose at a target quickly. These nozzles function like a ‘fourth control system’ complimenting the aircraft’s ailerons, rudders and elevators. The thrust vectoring is fully automated, allowing the pilot to concentrate on flying the aircraft and fighting.

The LL-PS modification aimed to explore supermaneuvrability by enhancing agility and control at high angles of attack.

Another advantage of a thrust-vectoring engine is the ability to control the aircraft without airflow – something traditional control surfaces are unable to do. This means that thrust-vectoring is especially useful in low-speed or high-altitudes where air is less dense and there is less pressure for the control surfaces on the wings to utilize.

However, the introduction of these nozzles required structural reinforcements and additional materials, which increased the aircraft’s overall weight, and also created an imbalance, since only one nozzle was modified. As mentioned earlier, these nozzles required lightweight materials that could withstand high-temperatures, leading to experiments with materials like carbon-carbon composites and advanced ceramics, but did not reach service and were still in development during the project’s timeline.

The AL-31F engines were also adapted to work with the thrust-vectoring system, optimizing performance for experimental purposes. In addition, the cockpit likely featured updated instrumentation to monitor the new system and gather data during test flights. These modifications provided valuable insights into thrust vectoring despite the challenges posed by increased weight and material limitations.

Conclusion

The Su-27LL-PS program was very short lived – it conducted around 20 sorties, with the first occurring on Dec. 31, 1989, and the program ending in 1990. The tests were all carried out at Zhukovsky Air Base. The program did not progress further due to technical and economic challenges. The NPO Motor-designed nozzles brought a significant loss of thrust (of 14 to 17%) due to its large size and a considerable increase in weight.

However, the flat nozzle also had some significant advantages over the circular nozzle. Specifically, it showed a significantly lower intensity of infrared traces. In addition, it could also serve as a thrust reverser. Furthermore, the main drawbacks of the movable flat nozzle in the form of high weight were not completely solvable, had the lightweight carbon-carbon and ceramic heat-insulating materials been introduced. Further studies on the movable nozzle conceived this way were stopped in favor of the circular nozzle – which would eventually be developed into 3D thrust-vectoring engines as well.

The little-known program represents a pivotal chapter in the advancements of thrust-vectoring. Although the program faced many significant challenges, it provided critical insights that informed future designs. Its legacy lies in the contributions to the development of the engines that power modern supermaneuverable fighters. The know-how gained from this project directly influenced subsequent contemporary Sukhoi platforms, like the Su-35 and Su-37.