This is how one of the most famous jet engines works.

Videos like the one below are interesting for several different reasons. They show the raw power of a jet engine working at different throttle/thrust settings, give a rough idea of the deafening roar generated by the reheat (you should be there to really understand how violent the sound is) and, above all, show the almost mesmerizing (at least to my eye) “dance” of the exhaust nozzles moving to open and close positions based on the engine regime.

This video was filmed a few years ago, hence it’s been around for some time; still it’s one of the most interesting to understand how variable exhaust nozzles work.

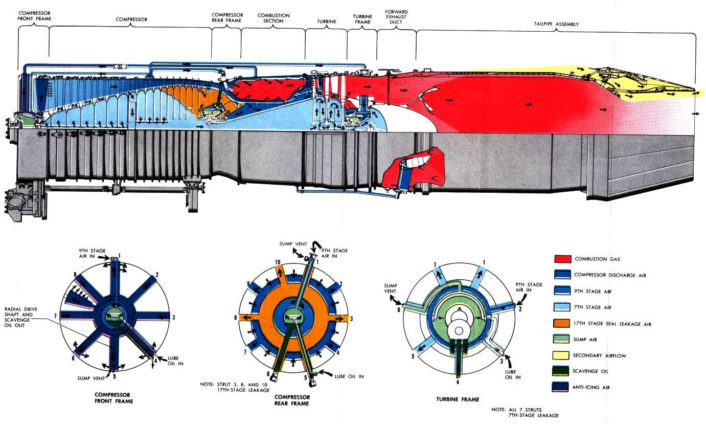

The engine being tested in the video, is a General Electric J79, an axial-flow turbojet engine, designed in the ’50s and used by several types of fightes and bombers across the world. The J79 equipped the B-58 Hustler, F-104 Starfighter, F-4 Phantom II, A-5 Vigilante, IAI Kfir and also a supersonic cruise missile, the SSM-N-9 Regulus II. It was a quite successful engine: more than 17,000 J79s were built in the US and under license in many other countries that operated aircraft powered by this engine. The production of the J79 lasted more than 30 years.

The video shows several interesting details. First of all, you can see the engine being started and then being tested at different “throttle positions”: as the thrust increases, the nozzles open incrementally to adapt the exhaust section and accommodate the fuel enriched re-ignited gasses. If the nozzles did not open after selecting the afterburner, the high pressure and temperature could cause the turbine blades to overheat and fail.

According to the datasheet data, the J79’s maximum thrust was 11,905 lbf (52.96 kN) dry; 17,835 lbf (79.33 kN) with afterburner. AgentJayZ, who tested the turbojet in the video above says that the fuel consumption was about 35-40 gallons per minute at full dry power (132-151 liters per minute), and 85-90 with afterburner (321-340 liters per minute!).

At 04.40 mark you can also spot a large white cloud in the exhaust: that is a mist of unburnt fuel, caused by the afterburner ignition not functioning.

The variable exhaust nozzles regulate the back pressure and velocity (based on the Venturi Effect, the higher the pressure, the lower the velocity and viceversa at subsonic airflow; the opposite happens at supersonic flow).

Here’s an excerpt from NASA website:

Most modern passenger and military aircraft are powered by gas turbine engines, which are also called jet engines. There are several different types of gas turbine engines, but all turbine engines have some parts in common. All gas turbine engines have a nozzle to produce thrust, to conduct the exhaust gases back to the free stream, and to set the mass flow rate through the engine. The nozzle sits downstream of the power turbine.

A nozzle is a relatively simple device, just a specially shaped tube through which hot gases flow. However, the mathematics which describe the operation of the nozzle takes some careful thought. As shown above, nozzles come in a variety of shapes and sizes depending on the mission of the aircraft. Simple turbojets, and turboprops, often have a fixed geometry convergent nozzle. Turbofan engines often employ a co-annular nozzle. The core flow exits the center nozzle while the fan flow exits the annular nozzle. Mixing of the two flows provides some thrust enhancement and these nozzles also tend to be quieter than convergent nozzles.

Afterburning turbojets and turbofans require a variable geometry convergent-divergent – CD nozzle [as the one in the video – Author]. In this nozzle, the flow first converges down to the minimum area or throat, then is expanded through the divergent section to the exit at the right. The flow is subsonic upstream of the throat, but supersonic downstream of the throat. The variable geometry causes these nozzles to be heavier than a fixed geometry nozzle, but variable geometry provides efficient engine operation over a wider airflow range than a simple fixed nozzle.

Therefore, generally speaking:

- nozzles are open at rest, with the aircraft standing still at the parking slot

- when the aircraft is on the ground taxiing under idle thrust, the diameter section is decreased (the nozzles close)

- when afterburner is selected, the nozzles open

- when in flight, the nozzle position remains to minimum diameter until afterburner is selected

Back to the J79, I had the opportunity to experience the “kick in the butt” effect of the engine taking off in the F-104 back in 2000. The acceleration the afterburner gave the Starfighter on take off was impressive. You could hear the noise of the engine in the cockpit through the flight helmet… After take off when the pilot sitting in the front seat deselected the afterburner the aircraft reacted with an abrupt reduction of speed and engine noise and the first thing I thought was that we were experiencing an engine stall and I would have to eject! Needless to say the J79 was working finely, but I wasn’t used nor prepared to the difference in thrust!

As any other jet engine with reheat, J79s with afterburner were particularly cool to watch at dusk or night, with their long flame glowing in the dark.