The United States Air Force A-10 was designed as a Close Air Support aircraft, built around a potent armor-destroying 30 mm rotating barrel cannon known as the Avenger.

Known as the A-10 ‘Thunderbolt II’ or, more affectionately, the ‘Warthog’, the Fairchild Republic Close Air Support (CAS) aircraft can carry a variety of ground attack munitions, but the primary weapon at its disposal is a Gatling-style rotary barrel General Electric cannon that rapidly fires rounds of depleted Uranium. The rapid firing, large quantities of propellant being burned, multiple moving parts, jarring recoil, and huge empty shell cases provide a challenge to both engineers and maintenance personnel.

An Aircraft Built Around a Gun

In 1970, the United States Air Force (USAF) issued a Request for Proposals (RFP) for the primary weapon of a CAS aircraft being developed under a program known as Attack Experimental (A-X). The weapon was to be an internal gun, as the lessons of Vietnam had caused the USAF to rethink previous deletions of aircraft guns on some fighter designs. The massive buildup of Soviet armor during the Cold War necessitated countering the threat with a deadly yet cost-effective solution.

Since the A-X project’s intent was for a CAS aircraft busting tanks and other armored vehicles, and the gun would be the aircraft’s primary weapon, the cannon would have to be a large one to punch holes in the latest Soviet armor developments. Specifications were for a 30 mm weapon capable of firing up to 4,000 rounds per minute (RPM) while achieving the accuracy standard with high velocity projectiles. The high rate of fire dictated a rotary cannon design, along with the need for sufficient ammunition storage for the large rounds. The rotary cannon design would also increase barrel life.

Four companies responded to the RFP: Hughes, Philco-Ford, General American Transportation, and General Electric — which had previous experience building rotary cannons for aircraft in the M61 20 mm gun. General Electric and Philco-Ford were chosen to as finalists to build competing prototypes, with the General Electric design, eventually designated the GAU-8/A Avenger, winning out in side-by-side firing trials in 1973.

The two prototype aircraft finalists of the A-X program, the Northrop YA-9A and the Fairchild Republic YA-10A, would be designed to carry the Avenger, although both aircraft would carry the M61 while the GAU-8/A was under development. The YA-10 would be chosen as the winner and designated the A-10 in production.

The General Electric GAU-8/A is mounted slightly to the port side of the fuselage of the A-10, occupying most of the central lower part of the fuselage. Being mounted to the port side allows the firing barrel to be aligned with the Warthog’s centerline. Having the firing barrel on the aircraft centerline reduces the heavy recoil effects the gun has on the flight of the aircraft, keeping it lined up on target. This contributes to the Avenger’s impressive accuracy. The gun’s recoil produces 10,000 pounds-force while the A-10’s two engines produce just over 9,000 pounds-force each.

In order to accommodate one of the largest and most powerful cannons ever fitted to an aircraft, and be installed in the frontal/lower area of the fuselage slightly to the port side, the front landing gear of the A-10 is offset to the right instead of being centered, retracting forward alongside the gun.

Armor plates of varying thickness are placed between the aircraft’s skin and the ammunition drum. This protects the rounds from enemy fire, with the drum extending rearward nearly 20 ft from the muzzle, almost to the front fuel tank mid-fuselage.

The GAU-8/A Avenger

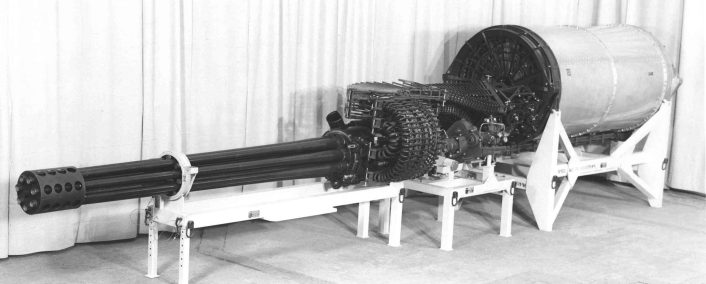

As previously mentioned, the GAU-8/A is a seven barreled rotary cannon firing 30 mm rounds. The gun follows Richard Gatling’s original design principles; the seven barrels all have their individual breech and bolt with the cocking and firing mechanism built into the bolt, with only one barrel firing at a time. As the bolt rams a loaded round into the breech and is locked in position, the cocking pin then compresses the firing pin spring.

A cam releases the trigger which then releases the firing pin, striking the igniter tube of the round which then ignites the main powder charge, causing the round to fire. The bolt then unlocks, travels rearward pulling the spent casing from the breech. Driven by two hydraulic motors, the barrels continue to spin repeating the cycle. Originally by operating only one of the motors, the firing rate could be slowed to about half from 4,200 to 2,100 rpm. However the rate of fire was later fixed to 3,900 rpm.

The drum is linked to a two-way feed system that returns the empty aluminum cases to the drum instead of ejecting them out of the aircraft. This is done to prevent the empties from striking the aircraft and causing damage due to their large size as well as preserving the aircraft’s center of gravity somewhat. Once the trigger is released, any live rounds loaded in the gun are reversed out back into the feed system. Capacity for the drum is up to 1,350 unlinked live rounds.

The GAU-8/A itself weighs in at approximately 620 lb, however adding the feed system and loaded drum magazine increases the weight to over 4,000 lb. Barrel length is 90.5 in and the entire system is 19 ft 10.5 in in length.

Rounds for the Avenger consist of training rounds that fire an aluminum projectile partially housed in a steel jacket. Armor piercing incendiary (API) rounds, known as PGU-14B, fire a projectile constructed of an aluminum body over smaller caliber depleted uranium core, with the total projectile weight being around 14 ounces (6,096 grains).

The PGU-13/B is a high explosive/incendiary round, consisting of a projectile constructed of a steel jacket packed with a high explosive/incendiary mix and an impact fuse at the tip. These projectiles weigh in at about 13.3 ounces (5,833 grains).

The projectiles have plastic driving bands embedded in them, with the original intent to reduce blinding muzzle flash, but it was found they reduce barrel wear so they were incorporated into the rounds. Cases are made of an aluminum alloy, reducing weight and adding 30% more ammunition capacity by doing so. Fully loaded, the rounds for the Avenger are 11.4 inches in length and weigh in at 1.53 lb or more.

Engineering Issues and Maintaining the Avenger

The large 30 mm cases contain a considerable amount of propellant, and having the gun at the nose of the aircraft means a lot of soot, smoke, and unburnt propellant are present at the nose of the aircraft during firing. This caused a couple of maintenance issues.

First, the soot from rapid firing the gun would accumulate on the forward fuselage, including the windscreen. This sometimes would obstruct the pilot’s view. A solution was found with a window-washing system that consisted of a cleaning solution and air bled from the aircraft’s propulsion system.

Another issue caused by the gases from firing the cannon was they would flow up over the wings and be sucked into the aircraft’s turbofan engines. Being mostly devoid of oxygen, the gases could suffocate the engines and shut them down. Attempts were made to deflect the gases with mixed results.

A solution was found by engineers in having the ignition system for the engines tied to the gun trigger, so that anytime the trigger is fired, the engine ignition system was initiated. The engines would immediately restart if stalled out by the fumes.

The GAU-8/A cannon are inspected and cleaned every 36 months or every 25,000 rounds by trained USAF maintenance personnel. Removable panels in the nose and front lower fuselage area of the Warthog allow access to the gun. The Avenger and its components can be completely removed from the aircraft and disassembled for cleaning, inspection, parts replacement, and lubrication.

The USAF specified the minimum barrel life of 21,000 rounds per set of seven barrels, so barrels and any worn parts of the gun can be replaced during the breakdown. The precession machined and rifled barrels are inspected with a bore scope. The hydraulic drive motors and ammunition drum and feed systems are also inspected, cleaned, and lubricated as required. Any damaged, rusted, or worn parts are replaced.

Recoil adapters must be inspected and adjusted to proper tension. These adapters help mitigate the effects of the extreme recoil and vibrations created by firing the GAU/8A, helping to prevent other parts of the gun and aircraft from coming loose, being damaged, or cracking. Tension equalizers must also be inspected to insure the slack remains the same in the Avenger while firing. Safety wires are installed to insure bolts do not become loose due to the extreme vibrations the aircraft experiences during the gun being fired. Loose parts could result in a misfire, damaging or destroying the aircraft.

Once the gun is reassembled, dummy rounds are fed through the cannon to ensure all components are adjusted and timed properly. Dummy rounds simulate the weight and shape of a live round, but allow testing and adjustments to be done safely. Live fire tests can also be conducted with the gun out of the aircraft. If everything functions, the gun and its components are reinstalled in the aircraft, putting it back in service and ready for duty.

While the GAU-8/A was designed for the A-10, variations of the gun have found their way into naval applications. The A-10 is slated for retirement soon, so the iconic ‘BRTTTTT’ sound made by the Avenger may soon be a thing of the past.