The goal of the test was to ensure the T-7A Red Hawk is fully capable and ready to perform its mission in representative climates.

The T-7A Red Hawk, the U.S. Air Force’s future jet trainer designed to emulate fifth-generation fighters like the F-35 and ease pilot training to operate newer generation fighters and bombers, underwent another round of climate tests at the McKinley Climatic Lab at the Eglin AFB in Florida between May 29 and Jun 17, 2025.

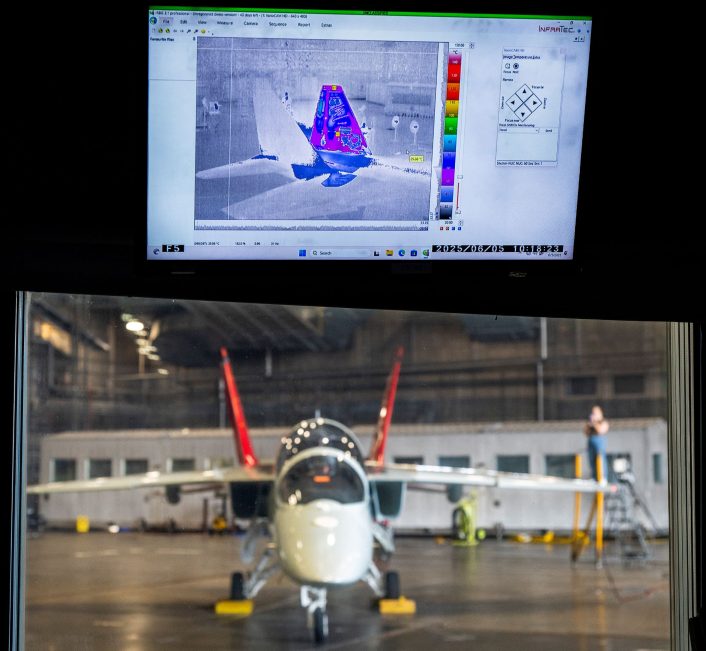

Held by the 96th Test Wing, the “extreme weather tests” with temperatures ranging from 110 degrees to minus 14 degrees Fahrenheit and 190 mile/hour manufactured winds are meant to verify the new “aircraft’s sustainability in any operational environment.” The “cold, heat and wind tests” at the 55,000 square foot test chamber, tested its tail fin in heavy crosswind, recreated “heavy humidity” to check its “instrumentation and electronics” and “icing” trials on the cockpit, according to the release and pictures that were published on the DVIDS network on Jul. 1, 2025.

A shot off a laptop screen showed a temperature rise on the vertical stabilizers, presumably after the sensors strapped on them were triggered during the crosswind testing. The previous such test of the Red Hawk was a “solar test” at the facility on Jan. 22, 2024, which saw the aircraft sitting under “bright lights used to create heat” and “temperature extremes from 110 to minus 25 degrees Fahrenheit.”

Just Chillin.’ ❄️

The #T7A Red Hawk just finished anti-fog, frost and ice ground testing with @TeamEglin in the McKinley Climatic Laboratory. The advanced trainer is being subjected to radical environmental conditions to validate its systems in varied climates. pic.twitter.com/G7JTzshG1k

— Boeing Defense (@BoeingDefense) June 23, 2025

Climatic tests

The press release called the T-7 a “Boeing test aircraft,” with the serial 21-7004 identifying it as the fourth Engineering Manufacturing Development (EMD) jet. The previous test involved the aircraft 21-7003, the third EMD jet.

The Director of Test and Evaluation of the Air Force Life Cycle Management Center’s Training Directorate Mike Keltos said the “goal is to ensure the T-7A Red Hawk is fully capable and ready to perform its mission in representative climates.” Boeing and Air Force air crew “performed system operations and engine runs to evaluate the aircraft’s reactions” while it endured the extreme environments created by the lab technicians.

Systems like an “icing spray system and wind tunnel” were used to simulate flight “through icing conditions by blowing a cloud of subfreezing temperatures on the aircraft canopy at flight speeds of over 160 knots,” the release explained. Boeing pilot Evan Thomas also opened and examined the frozen canopy during the cold weather phase of the tests on May 30.

The testing has an important reason, as it is needed to demonstrate the aircraft is safe to fly in every condition. “This experiment tests whether the pilots have sufficient visibility for flight and landing in extremely cold conditions,” explained the service.

Replicating these climate situations also required a significant amount of preparation in the test chamber, where “McKinley’s lab professionals create, break down, and recreate again each new test environment.” In fact, the release explained “technicians worked continuously to create negative temperatures, incredible wind speeds and a 110-degree desert inside of the hangar in less than a month.”

“McKinley Climatic Laboratory maintains quickness and technical proficiency by retaining our own staff of highly experienced welders, machinists, electricians, instrumentation experts, test assembly personnel and refrigeration operators,” said Melissa Tate, the lab’s flight chief. “Our main mission is to support the warfighter and to ensure any environment they encounter in the field; their equipment has already been proven in those extremes.”

The test chamber preparation and environment simulation is also different for different aircraft types, where the lab crews “accommodate and sometimes find new ways to support the specific requirements that may arise.” Aircraft like the F-117 Nighthawk, HH-60W Jolly Green, F-35 Lightning II have also been tested in similar simulated extreme temperature tests at the McKinley Climatic Laboratory.

T-7A Red Hawk acquisition and delays

These latest tests come after an Apr. 16, 2025 ejection seat trial by the 846th Test Squadron at Holloman AFB, which simulated an ejection at 450 knots. The test followed a string of delays and safety concerns raised in a Jan. 2025 Director of Operational Test and Evaluation (DOT&E) report.

While the test demonstrated the ability to protect both lighter and heavier pilot profiles, represented by test mannequins, it was specifically trialing two major upgrades: a redesigned canopy jettison system and an improved ejection seat sequencer. These are important parts in providing safety during an ejection.

The redesigned canopy is intended to shatter in a more controlled pattern, reducing the risk of injury from canopy fragments. Meanwhile, an updated sequencer allows a longer drogue chute deployment to stabilize the seat earlier in the trajectory, minimizing neck and spinal injuries during ejections.

The Air Force awarded a fixed-price contract to Boeing in September 2018 for 350 T-7A operational aircraft, spread across 10 fixed-price lots. The service is currently flying five test aircraft, with the last one delivered in December 2024.

“The T-7A will replace the T-38C, drastically improving training capability for the next generation of fighter and bomber pilots and will better prepare student pilots to advance into fourth and fifth generation fighter and bomber aircraft,” said Keltos.

The T-7A Red Hawk, meant to replace the Northrop T-38 Talon in service for 64 years, was originally planned to enter service in 2023-2024. However, its IOC (Initial Operational Capability) has now been scheduled for 2027. As per the USAF’s FY 2025 budget approved in 2024, the Lot 1 production contract for the T-7 Red Hawk was scheduled for 2025.

However, in January 2025, former Secretary of the Air Force Andrew Hunter revealed that the purchase of production specification airframes will be delayed until 2026. The 2025 budget had already halved the intended order from 14 to 7 units. In place of production airframes, the Air Force will acquire four Production Representative Test Vehicles (PRTV) in FY 2025, with an estimated delivery during FY 2026.

PRTVs allow Boeing to refine its production processes prior to the manufacturing of serial production airframes. They will also be employed by the Air Education and Training Command (AETC) for further trials and chalk a more concrete training curriculum ahead of the IOC.