The proof-of-concept, which involved a jet damaged after a belly landing, validated the feasibility of the F-35’s wing removal and reinstallation.

The Republic of Korea Air Force (ROKAF), the F-35 Joint Program Office (JPO), the U.S. Air Force and U.S. Navy worked together to successfully remove the wing of a divested South Korean F-35A jet that was repurposed as a maintenance training platform for the South Koreans, the JPO said in a release. The F-35A in question was deemed “unsuitable for continued operational service” following a bird strike in Jan. 2022 that necessitated “an emergency landing with the landing gear retracted.”

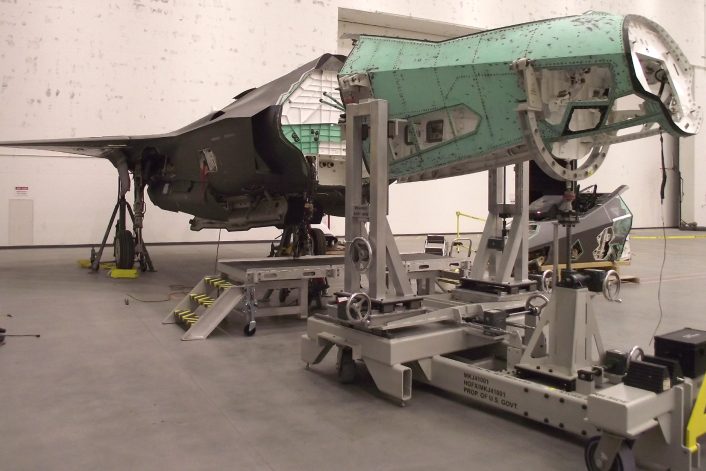

The successful removal will now be followed by the wings’ reinstallation at a new base where the airframe has been transported. The single image released on the DVIDS network on May 14, 2025 showed the F-35A with its wings detached and mounted on trolleys after the removal at an undisclosed location in South Korea. The vertical and horizontal stabilizers are also missing.

According to the press release, the team decided to “remove and later reinstall the aircraft’s wings” to overcome a “first major obstacle” represented by the relocation of the aircraft from one base to another. In fact, during overland transportation, if not disassembled, the aircraft’s wingspan would pose “significant cost and feasibility issues.”

Innovation meets resilience! 💪 👨🔬

In January 2022, a Republic of Korea Air Force (ROKAF) F-35A suffered a bird strike, rendering it unsuitable for continued service.

Rather than scrap the aircraft, ROKAF, the F-35 Joint Program Office, and experts pioneered a groundbreaking… pic.twitter.com/LZW4ZQfFIv

— F-35 Lightning II Joint Program Office (@theF35JPO) May 14, 2025

Notably, the JPO says the work was inspired from the technology and experience gained with the successful resurrection of the ‘Franken-Lightning’ project, which we reported extensively at The Aviationist. Here, an F-35A (AF-211/17-5269) that suffered a nose landing-gear in June 2020 was resurrected by being mated with the undamaged nose from another airframe (AF-27/10-5015) that suffered an engine fire in 2014 at Eglin AFB.

That successful resurrection led to the aircraft returning to full operational status after almost two and a half years. This inspired the “strategic decision” by the ROKAF and F-35 JPO “to repurpose the damaged airframe as a maintenance training platform for ROKAF personnel.”

Wing removal

As mentioned earlier, the project drew from the JPO’s experience with “prior reuse efforts,” and it was decided to replicate that effort for the ROKAF. Following approval from the service, its “damaged F-35A served as a testbed for this new capability […] that eventually enabled a safer and more cost-effective transfer.” The seemingly “straightforward concept” threw up “several logistical and technical challenges” during the transport to the new location, mentioned the press release.

A combined team from Lockheed Martin, the F-35 Lightning Support Team (LST), ROKAF Logistics Command, ROKAF’s 17th Fighter Wing, the U.S. Air Force’s 309th Expeditionary Deployed Maintenance Squadron, and the U.S. Navy’s Forward Deployed Combat Repair and Fleet Readiness Center Southeast, “successfully executed the wing removal process” in South Korea, explained the JPO.

Matt Trodden, LST Aircraft Crash Recovery Lead Engineer described the “proof of concept demonstration” as a “significant challenge, as it was the first attempt at removing F-35 wings.” However, “Despite early doubts, the team worked seamlessly and completed the operation several weeks ahead of schedule, validating the feasibility of wing removal and reinstallation,” Trodden said.

The damaged ROKAF F-35A

The ROKAF F-35A’s accident involved a belly landing on Jan. 4. 2022 at Seosan, after an eagle collided with its landing gear. Yonhap News Agency said that, while the pilot was safe, the mishap damaged 300 components, including the “airframe, structure, engine and control and navigation system.”

The report added that the ROKAF concluded it was more economical “to retire the aircraft than to fix it,” and save a whopping 140 billion won (US$107.6 million). However, at the time, the service was also considering “various ways to make use of the retired aircraft, including its potential use in mechanics training.”

South Korea purchased 40 F-35As from Lockheed Martin in 2014, in a deal worth $7 billion, with deliveries started in 2019. The Ministry of National Defense announced in March 2023 the decision to spend nearly $2.9 billion for an additional acquisition of 20 F-35As by 2028, as per Stars and Stripes.

Future

The proof of concept’s success, and to some degree the ‘Franken-Lightning’, project, has now vetted and codified the F-35’s wing removal and reinstallation procedures into the F-35 program’s “standard heavy maintenance, repair, and reuse protocols.” In fact, this has now demonstrated that “full wing replacement is a practical and effective capability within the F-35 sustainment framework,” according to the JPO.

As The Aviationist reported in context of F-35 17-5269 returning to operational status, the personnel at Hill AFB had to design brand-new tools and fixtures, with the work done at the Ogden Air Logistics Complex before the jet was returned to the 388th Fighter Wing in November 2023.

Unlike the stationary jigs used in the F-35 manufacturing plant in Fort Worth, these new tools were mobile and could be packed into a Conex box for use in forward operating locations. The equipment and technique have a huge utility for maintaining both U.S and Allied F-35s at forward locations both in the European and Indo-Pacific theaters.

Interesting pic of multiple South Korean F-35As flying without Luneburg Lenses (ie, in ‘stealth mode’), and seemingly showing no concern at North Korean radars collecting their signatures… pic.twitter.com/NniMhmWaPD

— Gareth Jennings (@GarethJennings3) January 26, 2023

The ROKAF F-35A’s wing removal and assembly mightl have involved some of the general technical protocols from that project, and particular ‘know-how’ and ‘know-why’ for handling the intricate wiring, joints and assemblies at the wing root. The F-35 JPO said this “milestone set a precedent for future F-35 repairs and global training initiatives, proving that even damaged aircraft can be revitalized through collaboration and ingenuity.”

Challenges

The involvement of primary contractor Lockheed Martin was required in order to have “all the pieces of the puzzle” for this unprecedented work. However, the F-35 showed in the past a continued dependency on the company, which former Secretary of the Air Force Frank Kendall in 2023 called an “acquisition malpractice” that created a “perpetual monopoly.”

A segment from the video that shows a ROKAF F-35A dropping an inert GBU-12, which scores a direct hit on a moving target (a surrogate ballistic missile TEL) at the Pilsung Firing Range. https://t.co/dVJrlB4NJf pic.twitter.com/t7brYSh2TL

— Guy Plopsky (@GuyPlopsky) April 19, 2024

Scaling up this pioneering maintenance work for the F-35’s global fleet of 1,150 jets, potentially reducing their downtimes and increasing aircraft availability, would not be possible until other secondary aerospace companies as partners and user Air Forces are passed down the technology. At the same time, Lockheed Martin cannot spare large teams of engineers to be deployed worldwide for several lightly damaged F-35s that could be quickly repaired and thrown back into combat during wartime.