The F-35 reconstruction project, expected to be completed in 2025, opens the door for repairing future mishap aircraft using tooling, equipment, techniques, and knowledge that has been developed.

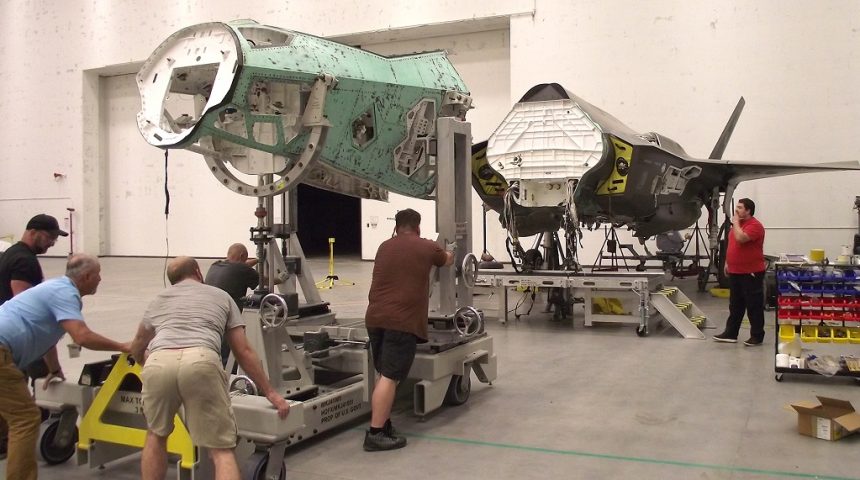

A team of maintenance experts from the F-35 Joint Program Office, the 388th Fighter Wing, the Ogden Air Logistics Complex and Lockheed Martin is working on an unprecedented project: stitching sections from two mishap damaged aircraft together into a restored, fully operational F-35A Lighting II. Previously, similar projects involved F-5Es of the U.S. Navy and a Finnish F/A-18, which was nicknamed the “Frankenhornet”.

After researching the feasibility, the F-35 JPO, working with the 388th Fighter Wing, opted to reconstruct AF-211, an aircraft that encountered a nose landing-gear separation in June 2020 at Hill AFB, Utah. The nose section of this aircraft is being replaced with the undamaged nose from AF-27, an F-35 that experienced a severe engine fire at Eglin AFB, Florida, in 2014, and is now serving as an Air Force Air Battle Damage and Repair trainer at Hill.

“This is a first for the F-35 program and a very exciting project,” said Dan Santos, F-35 JPO heavy maintenance manager. “It takes a team to make these types of endeavors successful. I am very impressed with the collaborative efforts from the various agencies across Hill AFB, working together to make this happen.

Over the past several years, the F-35 JPO has sought out new opportunities to repurpose useable parts and systems from damaged F-35 aircraft, for continued use and benefit to F-35 maintenance and operations, says the press release. This is similar to what has been done also by other program offices, which often transformed damaged aircraft in trainers. This particular project, says the Air Force, builds up on experience gained from several recent salvage aircraft re-purpose projects, including the stand-up of the first F-35 maintainer training facility using salvaged aircraft sections, as well as the partial restoration of a salvaged F-35 airframe for use as an ABDR (Air Battle Damage and Repair) trainer.

“Work began on the feasibility of this project in January 2020, when the F-35 JPO reached out to us because we had already accomplished the really big damage restoration projects for the F-22,” said Scott Taylor, Lockheed Martin lead mechanical engineer. “All of the aircraft sections can be de-mated and re-mated theoretically, but it’s just never been done before. This is the first F-35 ‘Frankin-bird’ to date. This is history.”

The Ogden Air Logistics Complex at Hill AFB has played a significant role by providing hangar space and heavy equipment for the project, however entirely new, unique specialized tooling, fixtures, and equipment have been designed and built, specifically adapted for mobility. The mobile fixtures can achieve the same results as the large, stationary automated manufacturing jigs used at the F-35 plant in Fort Worth, Texas.

The Air Force says these have potential future uses abroad, as the project’s meticulous documentation will be used to establish standardized F-35 procedures that can be seamlessly integrated into routine operations in the future. This project, according to the press release, is currently several months ahead of schedule and showing a completion date of March 2025.

“Not only will this project return a combat asset back to the warfighter, but it opens the door for repairing future mishap aircraft using tooling, equipment, techniques, and knowledge that has been developed,” said Santos.