Northrop Grumman tested the motor in the vacuum chamber in collaboration with the U.S. Air Force, continuing the development of the Minuteman III’s replacement.

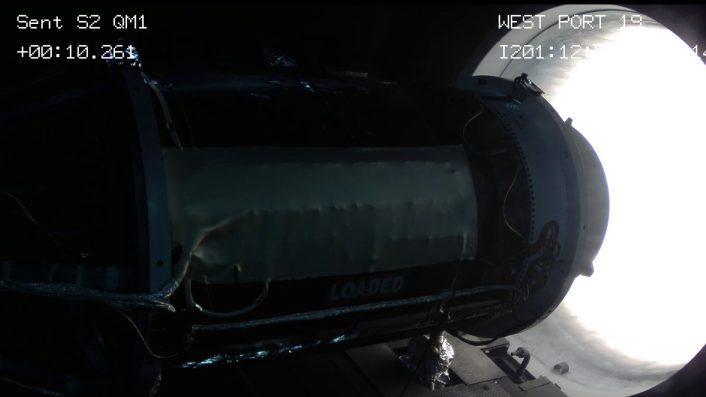

Northrop Grumman has test fired the second-stage solid rocket motor of the LGM-35A Sentinel ICBM (Inter-Continental Ballistic Missile) in collaboration with the U.S. Air Force at Arnold AFB in Tennessee. The full-scale qualification test was conducted on Jul. 20, 2025, and announced on Jul. 29 by both the company and the Air Force Nuclear Weapons Center (AFNWC).

Overseen by the 717th Test Squadron and the Arnold Engineering Development Test Complex, the ground-based fire of the Sentinel’s second stage rocket motor was “conducted in a vacuum chamber to simulate high-altitude conditions,” explained the Air Force. The test generated vital data on the “motor’s thrust, burn profile, and steering capabilities via its thrust vector control system.”

Additional stage-two qualification tests in the remainder of 2025 will “evaluate additional motor components under varied environmental conditions.” This stage has already been tested in a similar manner, according to January 2024 Air Force and Northrop Grumman statements.

The development follows the stage-one rocket motor’s full-scale qualification static fire test in Mar. 6, 2025 at Northrop Grumman’s Strategic Missile Test and Production Complex in Promontory, Utah. This validated the motor’s expected performance parameters with digital models, setting the stage for the latest stage-two trials.

The Sentinel team conducted a stage-two static test. Check out how we’re working with the @usairforce to reduce risk and fully qualify motor design.https://t.co/d9Gkg8lcZP

Photo courtesy of the U.S. Air Force. pic.twitter.com/CWhhOeCRgm

— Northrop Grumman (@northropgrumman) July 29, 2025

The company previously conducted a “shroud fly-off test” at Naval Air Weapons Station China Lake, a “stack test” at Promontory to evaluate the forward and aft sections, and wind tunnel test of the final stage’s vehicle holding the warhead. Northrop Grumman says the company and the Air Force have test-fired all three stages separately, validating digital engineering models and simulations to “improve performance, reliability, safety, and sustainability.”

Second-stage test

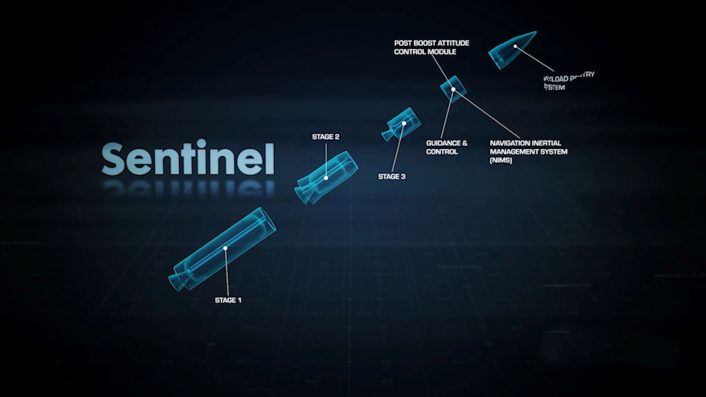

The LGM-35 Sentinel is a three-stage missile, thus including three booster segments. The latest test validated the second stage’ design and predictive performance models developed in a digital engineering environment, the AFNWC said. The testing data gathered will help “refine design elements and reduce technical risk as the program moves toward production.”

The Sentinel program’s model-based design approach helps “simulate system behavior, improve accuracy in performance predictions, and reduce reliance on costly hardware prototypes,” according to the AFNWC release. Northrop Grumman’s statement said digital engineering has helped avoid “bend metal” work for each design enhancement.

However, digital engineering can only supplement and not completely replace some tests. For instance, the live-fire qualification tests of the stage-two motor determine whether the components “meets the Air Force’s exacting standards for quality and reliability.”

“Northrop Grumman and the Air Force have tested all three stages of the Sentinel missile,” said Northrop Grumman’s press release. “This test is the first of a series intended to validate digital models and finalize the stage-two rocket motor design. Each test will verify different motor components to reduce risk and refine the design. This test follows earlier tests of both stage-one and development-stage motors, providing critical data for continued progress in missile design, testing and support systems

Similarly, the stage-one rocket motor tests conducted in Mar. 6, 2025, verified the digital engineering models and followed “static fire tests of the second and third stages, showcasing clear momentum in the Sentinel program’s development.”

The AFNWC statement quoted director of the ICBM Systems Directorate Brig. Gen. William S. Rogers, who said the latest test “reflects our disciplined digital engineering approach and the continued momentum behind the Sentinel program.” Additionally, Rogers explained “we’re not just testing hardware (but) proving that our models are accurate, our development timeline is achievable, and the system will be ready to deliver.”

We’re partnering with the @usairforce to deliver Sentinel —an ICBM system providing game-changing capability, needed improvements for missileers and strategic deterrence against evolving threats through 2075. https://t.co/3p6CyVqExk pic.twitter.com/8muFiePLkE

— Northrop Grumman (@northropgrumman) June 18, 2025

Other tests

As mentioned earlier, the Air Force and Northrop have demonstrated all propulsive elements of the Sentinel missile. These tests are part of the engineering, manufacturing, and development (EMD) phase of the program.

Beside the test firing stages-one, two and three, a “hot-fire” of the Post Boost Propulsion System (PBPS) has also been conducted. The liquid fuel PBPS propels the Post Boost Attitude Control Module, “responsible for positioning the reentry vehicle during exo-atmospheric flight,” according to Northrop.

Interstage separation tests of the Sentinel missile demonstrated its ability to “cleanly separate the spent solid rocket motor stages one and two from the rest of the vehicle, critical to the flight staging sequence.” Wind tunnel tests of scale models of the last stage vehicle, which carries the warhead, checked it under sub-hypersonic to hypersonic speeds to match the design’s maturity with digital modelling and simulations.

Lastly, the joint Northrop and Air Force team also inspected 16 existing silos and used those observations to build a mock-up of a Minuteman lower launch tube at Hill AFB, Utah. The tube “included a variety of built-in conditions to simulate wear and tear.”

Sentinel ICBM’s massive infrastructure

The U.S. Air Force said in the past it was willing to conduct a staggering amount of Sentinel-centric infrastructure work like underground launch silos, entailing excavations at or beyond 80 feet deep at around 400 sites across continental U.S. Existing Minuteman III silos are based in Wyoming, North Dakota, Montana, Colorado, and Nebraska. New silos would be required also at Vandenberg SFB for test launches.

A major driver of the 81% spike in the Sentinel’s estimated cost to $140 billion that triggered a Nunn-McCurdy Review, beside the unforeseen new silos and command and control facilities, was also represented by the related maintenance equipment, communications suites, encryption systems, electronics, software, wiring and cabling systems.

Speaking at the Advanced Nuclear Weapons Alliance Deterrence Center on Apr. 30, 2025, AFSC (Air Force Global Strike Command) Gen. Thomas Brussiere also ruled out the option of reusing the older silos holding the existing Minuteman III ICBMs – a route it presumably briefly considered.

“Part of the requirements, initially – ten years ago when this program was started – was to reuse the holes, the missile holes at the launch facilities,” explained Brussiere. “That was believed to be more efficient, more cost effective and quicker. Shockingly enough, if we look at it now, that may not be the answer.”

The Air Force has yet to take its decision on that front or, if it has already, has not yet made it public. Northrop Grumman, in a Jun. 2025 video on the Sentinel, has put the total number of missiles at 450, an equal number of unmanned launch facilities and 24 all new LCC (Launch Control Centers) – reflecting what the entirety of what the gigantic program encompasses.

Fiber optic cables 5,000 miles long meanwhile will connect launch facilities and LCCs across the 91st Missile Wing, 341st MW and 90th MW, covering 32,000 square miles across five states.