After a lengthy restoration started with a feasibility study in 2020, the F-35 AF-5269 was sent to Lockheed Martin for final certifications before returning operational with the 4th Fighter Squadron at Hill Air Force Base.

The U.S. Air Force has just announced the completion of the lengthy project to restore a single F-35A Lightning II from two separate, damaged aircraft, and begin its return to the operational fleet. The acknowledgement comes after our friend and contributor Victoria Fontana caught the interesting F-35A, also known as “Franken-Lightning”, taxiing at NAS JRB Fort Worth, where it was sent for final certification by Lockheed Martin.

The “Franken-Lightning”

As we previously mentioned in other articles here at The Aviationist, the “Franken-Lightning” is the aircraft AF-211, or 17-5269, an aircraft that encountered a nose landing-gear separation in June 2020 at Hill AFB, Utah. The nose section of this aircraft was replaced with the undamaged nose from AF-27, or 10-5015, an F-35 that experienced a severe engine fire at Eglin AFB, Florida, in 2014, and is now serving as an Air Force Air Battle Damage and Repair trainer at Hill.

The Air Force highlighted the fact that such restoration was unprecedented, as it was the first time maintainers have successfully pieced together two F-35A structures to generate an operational aircraft. The project was an interagency effort between the F-35 Joint Program Office, Ogden Air Logistics Complex, 388th Fighter Wing and Lockheed Martin.

“When we took responsibility for this project, we were taking on something unprecedented at the field level and it wasn’t easy. That can’t be overstated,” said 1st Lt. Ryan Bare, Sortie Generation Flight commander for the 4th FGS. “But, we were also taking on an opportunity for our maintainers to gain proficiency in this type of work and build experience at the unit level. As a program, and as a unit, we’ve benefited greatly from this.”

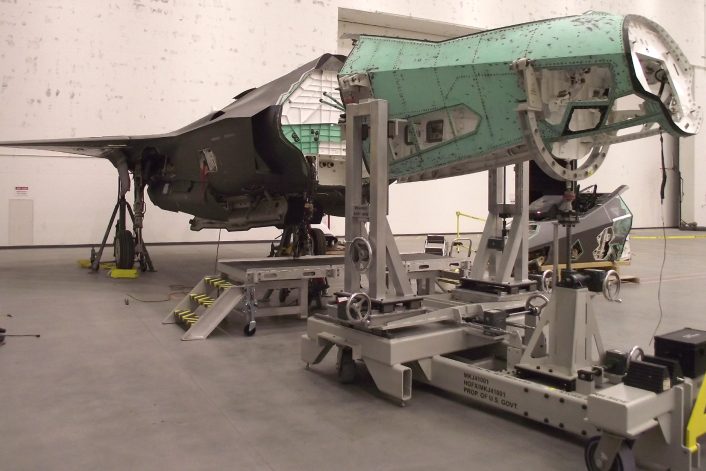

The team at Hill Air Force Base had to design brand-new tools and fixtures specifically for this project. The service added that this work was done at the Ogden Air Logistics Complex before the jet was returned to the 388th Fighter Wing in November 2023.

Unlike the stationary jigs used in the F-35 manufacturing plant in Fort Worth, these new tools were mobile and could be packed into a Conex box for use in forward operating locations. £The resources and techniques pioneered during that stage of the project have potential for future use in aircraft battle damage repair at forward locations,” said Scott Taylor, Lockheed Martin’s lead mechanical engineer on the project.

Once returned at Hill AFB, the aircraft was hangared in the 4th Fighter Generation Squadron, where maintainers worked on the final stages of its restoration. Lots of work were still to be done, like re-installing the landing gear with the proper aircraft center of gravity, procuring and installing “belly bands” and flight controls, rewiring the aircraft, rebuilding the cockpit, avionics computers and installing a variety of other components.

“When we received the aircraft, it was pretty much a shell,” said Senior Airman Jaguar Arnold, the aircraft’s dedicated crew chief from the 4th FGS. “There were a lot of tasks to complete that we hadn’t done before at the unit level.”

Once the work at Hill was completed, AF-211 performed a successful functional check flight and then headed to Lockheed Martin’s facility in Fort Worth, Texas, for final certifications. Once the company clears it, the F-35 will return to Hill and will be flown by the 4th Fighter Squadron.

More than just an aircraft restoration

The huge effort required for the restoration will have lasting effects also for the rest of the fleet, as Airmen were able to provide feedback to the JPO that will be used to update the Joint Technical Data used by all F-35 maintainers when installing and inspecting new components. Also, the project is estimated to have cost under $6 million dollars, way less than the over $80 million of a new F-35.

Over the past several years, the F-35 JPO has sought out new opportunities to repurpose useable parts and systems from damaged F-35 aircraft, for continued use and benefit to F-35 maintenance and operations, says the press release. This is similar to what has been done also by other program offices, which often transformed damaged aircraft in trainers.

The Air Force already said in 2023 that this restoration would have potential future uses abroad, as the project’s meticulous documentation will be used to establish standardized F-35 procedures that can be seamlessly integrated into routine operations in the future. This is especially important as not only it can save millions in taxpayer dollars, but it also enhances the readiness of the fleet. It could even have positive effects in the event of a high-end conflict, allowing quicker repairs of battle damage.