We asked a retired NCIS agent about his experience fighting the proliferation of counterfeit and critical fraudulent parts in the U.S. military.

A retired special agent with the Naval Criminal Investigative Service (NCIS) wrote an article in the January/February 2023 edition of Fraud Magazine entitled “Battling Fraudulent Product Substitution“. In the article, Stewart Thompson talks about his experiences using proactive approaches to combat product substitution at Naval Air (NAVAIR) Systems Command in Patuxent River, Maryland.

Product substitution is different from other types of procurement fraud, such as price fixing, cost mischarging, bribery, and subcontractor kickbacks. Counterfeit/non-conforming parts can mean the difference between life and death, especially when installed in military aircraft and weapon systems. According to Thompson, aggressive enforcement in the form of proactive operations is often the most effective way to stop these bad actors; sometimes, it’s the only way.

Product substitution is just as much a threat to mission readiness, loss of life and aircraft, and national security today as it was a dozen years ago, especially in the throes of a global supply chain crisis and an increased demand for obsolete chips. We asked Stewart Thompson some questions to highlight the most important takeaways from his article.

Q. What factors contributed to the success of the NCIS/NAVAIR proactive product substitution model?

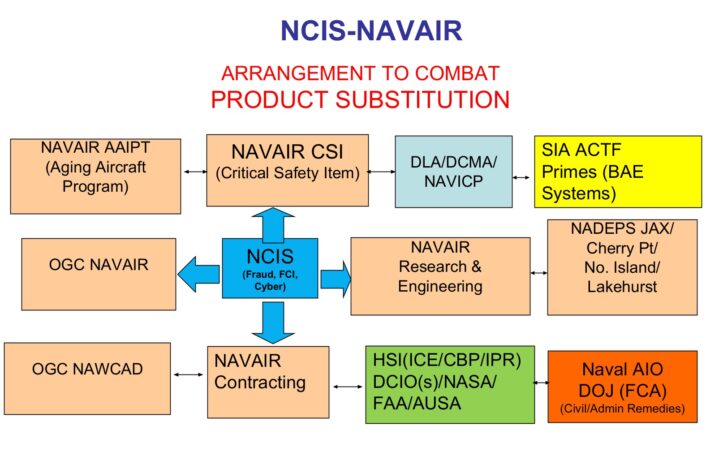

It was the first time that NCIS’s Fraud, Cybercrimes, and Foreign Counterintelligence Divisions worked together on the problem of counterfeit/defective parts in the DOD supply chain. Former Assistant U.S. Attorney (AUSA) Sherri Schornstein described the work as “groundbreaking”. Second, NCIS collaborated with a variety of organizations within and outside of NAVAIR. Third, the visionary leadership of NAVAIR Commanders ADM Walter Massenburg and ADM David Venlet, set a strong moral tone at the top. This culture of safety fostered an overriding concern for product integrity and led to the creation of the Critical Safety Item (CSI) Office in which special emphasis was placed on critical parts to prevent catastrophic loss of life and aircraft. Fourth, the embedded NCIS agent proactively recruited sources, interviewed witnesses, made undercover buys, and researched red flags such as a disproportionate percentage of deficiency reports, failed tests and inspections, prior criminal investigations, and terminations for default and convenience, which led to the identification of suspect contractors.

Q. Can you tell us how the first case that NAVAIR/NCIS worked on together to stop the trafficking of counterfeit integrated circuits to the U.S. Military got started?

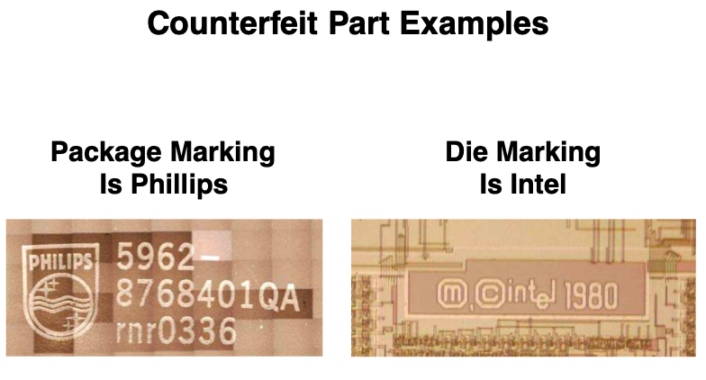

As background, in 2006, the Semiconductor Industry Association (SIA) created an Anti-Counterfeiting Task Force to coordinate with law enforcement in the investigation of counterfeit semiconductors. I had given fraud briefings to NAVAIR’s Office of General Counsel (OGC) and Systems Engineering Division. Subsequently, BAE Systems, a prime Government contractor, and a NAVAIR engineer contacted me and reported receiving suspect counterfeit microcircuits from a broker that had purchased them from VisionTech Components. The application of these parts was for use in military aircraft computers to identify hostile aircraft, Identification Friend Foe (IFF). I seized the suspect parts, along with Certificates of Conformance (CoC), as evidence. A SIA member, an original component manufacturer (OCM), tested the parts and determined they were counterfeit. In coordination with Homeland Security Investigations (HSI) National Intellectual Property Rights Coordination Center (IPRC) and the Assistant U.S. Attorney’s Office, NAVAIR/NCIS made additional covert purchases of microcircuits from VisionTech, which SIA also tested and identified as being bogus.

Q. Can you give other examples how the NCIS/NAVAIR teaming arrangement improved mission readiness and potentially saved lives?

One SIA member reported that the Defense Logistics Agency (DLA), which buys parts from manufacturers and suppliers for the warfighter, had procured counterfeit digital microcircuits from vendors that were subsequently requisitioned by Hill Air Force Base and used in several U.S. Air Force platforms. NCIS immediately notified the AF Office of Special Investigations (OSI) and DLA’s Fraud Counsel.

In another instance, a company that supplied catapult equipment, critical to aircraft safely taking off and landing aboard ships, to the DLA, failed to weld JBD (jet blast deflector) brackets in accordance with the drawing specification; the failure of these parts resulted in extensive damage to a carrier and adversely impacted mission readiness for all carriers in the fleet. NCIS/NAVAIR worked with NAVAIR Depot Lakehurst to conduct inspections, make emergency repairs, provide engineering support, and quarantine the discrepant parts as evidence in a potential criminal proceeding.

In addition, DLA created emergency funding to produce/procure additional parts. NAVAIR Lakehurst issued a Category 1 Product Quality Deficiency Report (PQDR), because of the potential for loss of life, mission and property and issued a special bulletin to all carriers to replace the defective parts. In yet another case, DLA supplied NAVAIR Depot Jacksonville with sheets stamped as being carbon steel. Since DLA and the contractor provided no CoCs or test reports, and its intended use was for a CSI application (retainer tube for fighter aircraft), engineering tested a sample. The material failed chemical analysis and did not even qualify as carbon steel. The contractor had marked the material to make it appear as though it were consistent with contract specifications. Yet, without testing, one would have never known that the part had been manufactured out of the wrong material.

Q. Can you describe methods that counterfeit integrated circuits (IC(s)) have been introduced into the DOD supply chain?

Investigations revealed that electronic waste (e-waste) that is shipped from the United States to China is often returned to the U.S. in the form of counterfeit parts. For example, circuit boards are heated over flames or with soldering irons to remove the electrical components, which are then washed in rivers or left out in the rain and humidity. The ICs are then sanded and remarked, often with military-grade markings, to make them appear as new, so they can be sold at a premium price. The electrical components are then exported from China to waiting distributors in the U.S., which sell them to other distributors or to DOD prime contractors. Another method is for distributors to harvest the dies from semiconductors by drilling and de-caping the case and removing the guts. The die is then shipped to Thailand with remarking/encasement instructions and then returned to the DOD distributor in a “like new” condition for resale. In another instance, a contractor ground down markings of genuine lower speed computer processors and remarked the components to make them appear as though they operated at a higher speed to conform with contract specifications.

Q. Are there steps that Congress and industry can take to mitigate the threat of non-conforming/counterfeit parts in the DOD supply chain?

Congress has taken some action since the Senate Armed Services Committee (SASC) released a report in 2012 detailing 1,800 instances of suspected counterfeit parts found in the military between 2009 and 2011. This has resulted in the passage of the National Defense Authorization Act (NDAA) – 2012 and amendments to address weaknesses in the DOD supply chain, i.e., requiring contractors to purchase semiconductors from OCMs or their licensed distributors “whenever possible” and to implement a counterfeit avoidance testing and reporting programs.

In addition, Congress passed a bill, enhancing penalties for criminals, recognizing that selling counterfeit military components should be treated differently than selling other counterfeit products, because it poses a more serious risk to health, life, and national security. Since the SASC hearings, several recycling export bills have been introduced in the House to stop the flow of e-waste to China; none of the bills have passed.

The latest bill, The America COMPETES Act of 2022, contains language to stop the flow of e-waste to China and other countries that are known to counterfeit electronics; however, the House and the Senate have been unable to agree on common language in the conference committee. In addition, NASA and the DOD have adopted Society of Automotive Engineers (SAE) AS5553(A) and other aerospace standards, which standardize practices to detect, mitigate, avoid, procure and report counterfeit electronic components.

Would it be possible for Congress to build on the semiconductor counterfeit legislative language to require purchases of critical safety items, such as mechanical components, to be traceable to the OCM or Original Equipment Manufacturer (OEM)? It seems reasonable for Congress to mandate that DOD maintain traceability documentation for CSI fasteners, O-rings, and electrical connectors, showing evidence of manufacturing and quality certifications from the authorized manufacturer through all intermediate levels to delivery to DOD. In addition, a requirement for the Defense Contract Management Agency (DCMA) to conduct physical product inspection of CSIs, at least randomly of CSI distributors/manufacturers, is something Congress might consider legislating.

Q. Your article points out the difficulty of establishing “intent to defraud” in a criminal prosecution. What are some ways that prosecutors can prove “intent to defraud”?

Criminal cases require that the defendant have a specific intent to defraud. It’s a high bar. Fraudulent intent can be inferred if, for example, a contractor uses various company names to import counterfeit microcircuits into the United States to thwart detection by Customs and Border Protection (CBP) inspectors. In another example, CBP gives contractors the opportunity to contest seizures of suspected counterfeit goods. Should the companies decline to challenge them, then it may be suggestive of a guilty mind.

In addition, if OCMs mail certified or registered “cease and desist” letters to contractors that are allegedly infringing on the OCMs’ trademarks and the contractors continue to import suspected counterfeit parts, then it suggests that they are aware of the criminal scheme. Another potential example of fraudulent intent is DOD quality inspectors examining and rejecting a contractor’s parts as failing to conform to contract specifications; however, despite this, the contractor ships the same parts to the military under a destination acceptance contract or sells them to a DOD distributor along with a falsified CoC.

Interviews of former and current employees of a suspect contractor have also been valuable sources of information to show evidence that a contractor failed to conduct contractually required testing and falsified test reports. In addition, making several undercover buys of non-conforming parts from a suspect contractor is important to show that the first buy of defective parts wasn’t an accident; this repeated pattern of illegal conduct makes it easier to obtain a criminal conviction and has a general deterrent effect on other bad actors thinking about engaging in similar criminal activity.