The U.S. Air Force’s new CSAR (combat search and rescue) helicopter experienced temperature extremes from 120 to minus 60 degrees Fahrenheit as well as torrential rain during the month of testing inside the McKinley Climatic Lab.

As we have briefly explained in a previous article about the deployment of the new AN/AAQ-45(V) Distributed Aperture Infrared Countermeasure (DAIRCM) to the HH-60G fleet, the Pave Hawk helicopters will be replaced by the HH-60W Jolly Green II. The U.S. Air Force’s initial plan was to buy 113 helicopters but it has recently said it will only acquire up to 108 of the Jolly Green IIs with the first two currently undergoing test and evaluation and deliveries of operational aircraft starting later this year.

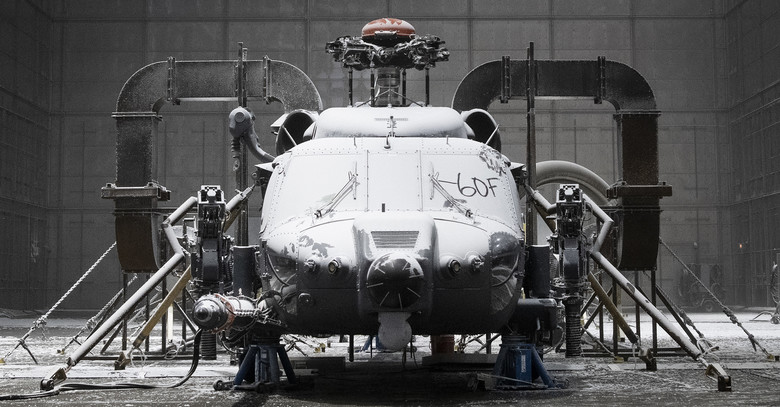

Part of the developmental test program (a joint effort between Sikorsky, the 413th FLTS, the 88th TES and Air Force Operational Test and Evaluation Center), saw the brand new chopper move to Eglin Air Force Base, for a month-long trial of extremes inside the McKinley Climatic Lab’s 55,000 square foot test chamber. According to an official note, the Sikorsky test aircraft endured real temperatures ranging from 120 degrees to minus 60 degrees Fahrenheit as well as 45 mph winds coupled with heavy rainfall.

With their peculiar mission to rescue people in all weather, HH-60Ws have to be able to safely and efficiently operate in all conditions, including extreme ones that might be found stateside or abroad. Avionics, engine, sensors, radio gear: every system and equipment is required to work in freezing conditions. Including aircrew:

“Operating the HH-60W in the extreme conditions was a truly unique experience as a pilot and a tester,” said Lt. Col. Ryan Coates, an 88th Test and Evaluation Squadron pilot, who performed most of the testing. “Checking system performance under the stress of heat, cold, heavy wind and rain will give us real-world data regarding the helicopter’s capability to perform the rescue mission worldwide in various environments, which is exactly what the operator needs to make solid employment decisions.”

For example, the cold-weather gear worn by the aircrew is much bulkier than a standard flight suit. One of the evaluations was to ensure the pilots could easily reach all of the aircraft controls in the thicker cold-weather gear.

The Lab can create different weathers: from the 100F desert temperatures to the freezing icebox. But the “conversion” of the chamber is not easy and requires three days of work. Moreover, the form and size of the aircraft being tested may require some tweaking. In fact, the HH-60W Jolly Green II created some unique challenges for McKinley Lab personnel: the lab technicians created a system specifically for the HH-60W to remove the aircraft’s exhaust because “thorough exhaust removal is a critical part of maintaining the controlled temperature conditions needed for chamber testing, according to lab technicians working on the test. The design of the ventilation system meant the aircraft’s blades were removed for the duration of the testing. The lab’s in-house fabrication shop also specially designed brackets for the aircraft’s weapons among other items,” says the official USAF news release.

After testing in the climatic lab at Eglin AFB, the HH-60W will return to Sikorsky’s test facility in West Palm Beach for further evaluation. Test aircraft are primarily split between Duke Field (part of Eglin) and Sikorsky’s West Palm Beach facility.