Investigators say a hydraulic fitting failure set off the 2022 B-2 incident at Whiteman AFB, ending in a gear collapse, wing fire and $300M repair bill.

The U.S. Air Force has released the Accident Investigation Board (AIB) report into the B-2A Spirit mishap at Whiteman AFB on Dec. 10, 2022, providing a detailed, technical reconstruction of events from approach to firefighting. The findings point to a hydraulic fitting failure that triggered a cascade ending with a main-gear collapse on landing, a wing fire and significant damage to the aircraft. No injuries were reported.

Events

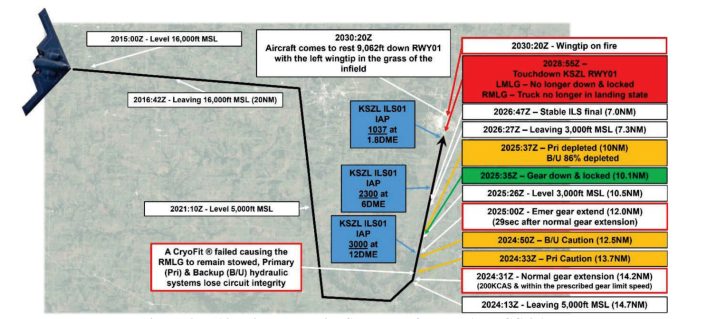

According to the AIB, tail number 90-0041, callsign DEATH 12, launched at about 0700 local as the airborne spare for a long-range mission and returned to Whiteman once the primary aircraft continued, as planned. The approach to Runway 01 was uneventful until the crew selected gear down at roughly 200 KCAS (within limits). Immediately afterward, the aircraft presented a master caution and hydraulic system cautions indicating a leak. The left main and nose gear extended; the right main gear did not. The crew executed the emergency extension, after which all three gear indicated down and locked, and the aircraft was cleared to land.

Touchdown occurred near the 1,000-ft markers at about 1429 local. On contact, the left main landing gear (LMLG) collapsed. The left wing then contacted the surface and the aircraft departed the paved surface before coming to a stop with the left wing in the grass infield. The crew egressed without injury. The AIB notes the engineering parameters at landing (speed, attitude and recorded loads) did not indicate a hard landing, focusing attention instead on the landing-gear system behavior following the prior emergency extension.

The report attributes the initiating event to the expulsion of a hydraulic coupling associated with the right main gear truck position sequence valve. The expelled sleeve opened a path for hydraulic fluid to be pumped overboard, first from the primary hydraulic system and then from the backup system as the flight-control computers switched sources in response to falling pressure. The leak prevented the right main gear from unlocking in the normal sequence and drove the crew to use the emergency extension. Follow-on materials analysis found circumferential “witness marks” on the T-fitting consistent with a single expulsion event; no microcracking or surface flaws were identified in the recovered coupling itself.

Why the left main failed after an apparently successful extension

The AIB’s technical analysis focuses on what happened inside the landing-gear hydraulics during emergency extension. When the system shifted to the emergency bypass configuration, the pressure that normally helps hold the left main’s lock link in an over-center (locked) position rapidly dropped. That change allowed the lock actuator to relax slightly before landing. On touchdown, a brief pressure pulse associated with truck-beam movement and the truck-position actuator return flow pulled the lock link further out of over-center, overcoming spring tension and leading to the LMLG collapse. In short: the emergency extension resolved indications, but the left main no longer had the hydraulic margin it normally retains through landing.

As the wing dragged, the underside skin abraded across unprepared surface and concrete, rupturing the left surge tank under the wingtip. A fuel fire started and later involved the left outboard tank. Aircraft rescue and firefighting (ARFF) units responded promptly. The incident commander initially directed water application; Aqueous Film Forming Foam (AFFF) was authorized approximately three minutes and 28 seconds after the start of the attack, once the fire was assessed as fuel-related. External flames were substantially reduced with foam, but heat within the wing continued to build. The left surge tank then exploded, followed by the left outboard tank roughly ten minutes later. The second explosion blew a section of upper wing skin free, after which firefighters were able to access and extinguish the internal fire; the fire was out approximately one hour after it began. No responders were injured.

Damage and cost

The left wing sustained major structural damage, along with damage to control surfaces and the left main-gear doors and actuators. The AIB’s estimate places aircraft damage above $300 million; airfield damage was approximately $27,500.

The AIB president finds, by a preponderance of evidence, that the mishap was caused by the failure of the truck position sequence valve’s CryoFit coupling, which led to hydraulic loss, an emergency extension, and subsequent conditions that allowed the left main to collapse on touchdown. Two substantially contributing factors are cited:

- landing-gear design vulnerabilities that permitted the left main lock link to move out of its required over-center position during emergency configuration, leaving it susceptible to collapse; and

- a delay in employing AFFF, which allowed the fire to spread and increased external damage. The board notes there were no known deviations from directives or policy by aircrew or maintainers that contributed to the mishap.

The report also explains that immediate use of foam would have reduced external damage but would not have changed the outcome inside the sealed tanks; the internal fire was responsible for the explosions that occurred despite the external attack. The board further records that one ARFF vehicle with a piercing nozzle was unavailable due to a maintenance issue and another suffered a pump failure during the response. Technical guidance for B-2 wing/fuel-tank piercing is limited, which left uncertainty over how a penetrating nozzle might have been employed even if available.

The AIB report focuses on the technical chain of events, damage assessment and firefighting response but it does not document the base’s operational status after the mishap (runway closure duration, reopening timeline, or the subsequent fleet stand-down).

However, as we covered in details, in the immediate aftermath, Whiteman AFB’s only runway was closed, initially via NOTAM through Dec. 16, later extended to Dec. 31, 2022, while Air Force Global Strike Command ordered a safety stand-down of the entire B-2 fleet.

A few days later, the base announced that the runway had reopened on Dec. 21, 2022, allowing A-10 and T-38 flying to resume, while the B-2s remained grounded pending inspections. Subsequent reports highlighted the runway had been closed 11 days in total and that B-2 flight operations resumed on May 22, 2023, after roughly five months of stand-down.

CryoFit fittings and maintenance

CryoFit sleeve couplings are used widely in the B-2’s titanium hydraulic plumbing. Installed cold and shrunk into place, they create a mechanical bite into the adjoining tube or fitting. The AIB describes the installation method and notes that, in this case, laboratory inspection did not identify material defects in the expelled sleeve; witness marks suggested a single-event expulsion. The report does not attribute the mishap to maintenance error; preflight servicing and inspections complied with technical orders, and the aircraft launched without discrepancies.

Procedural takeaways

According to the report, system indications can be necessary but insufficient: all three gear showed down-and-locked after emergency extension, but the left main no longer retained its full locking margin, information not directly captured by cockpit status. Second, firefighting agent selection matters on fuel fires. The AIB underscores that Air Force policy did not prohibit AFFF’s early use; the incident commander’s initial hesitation was based on an interpretation later identified as an “unwritten policy” issue.

Summing up…

The Whiteman mishap was initiated by a hydraulic coupling failure and compounded by the way the landing-gear system behaves when shifted to emergency hydraulics. The subsequent fire damage reflects both the mechanical damage from the gear collapse and the timeline of firefighting actions. The AIB’s recommendations focus on engineering analysis of the landing-gear hydraulics in emergency mode, review of fittings, and clarity in ARFF training for agent selection and access on low-observable airframes.

Readers may recall a previous Whiteman incident on Sept. 14, 2021, when B-2A 89-0129 “Spirit of Georgia,” assigned to the 393rd Bomb Squadron, suffered a left main landing gear collapse on touchdown and skidded off the runway. We reported the AIB’s finding that old/weak lock-link springs on the left main were the primary cause, with damage estimated at about $10 million; both pilots were uninjured. The jet came to rest off the pavement roughly a mile from the touchdown point, prompting a runway closure while recovery operations took place.