A report of the DoD IG says spare parts shortage decreased the B-52’s availability rate and increased the need to cannibalize other aircraft.

On Nov. 28, 2023, the Department of Defense Office of Inspector General released a report about the U.S. Air Force’s management of the B-52 Stratofortress bomber’s spare parts. The report, titled “Audit of B-52 Diminishing Manufacturing Sources and Material Shortages,” identified that the U.S. Air Force did not effectively manage diminishing manufacturing sources and material shortages (DMSMS) for the B-52 and this contributed to spare part shortages.

DMSMS, as explained in the report, refers to the loss, or impending loss, of the last known manufacturer or supplier of raw materials and other critical components for production or repair parts.

The B-52 entered service in 1955 and the last bomber was delivered in 1962. Many of the original manufacturers of the B-52’s parts no longer exist, while other companies discontinued production for some spare parts, so this made harder and more expensive for the Air Force to find replacement spare parts.

When it entered service, the B-52 had a projected lifespan of 20 years, says the report. However, because the B-52 remains a critical asset in national defense due to its ability to adapt to emerging threats, the Air Force plans to keep its remaining fleet of 76 B-52 bombers (out of 744 produced) in service until 2060, when the average age of the aircraft will be 100 years.

“Despite its age, the B-52 remains a cornerstone in the Air Force’s arsenal,” said Inspector General Robert P. Storch. “While the Air Force’s $48.6 billion modernization plan for the aircraft may enhance its capabilities, the supply chain challenges identified in this audit could impact the Air force’s ability to keep the aircraft flying.”

The audit highlighted several concerns regarding the management of B-52 spare parts and, specifically, the B-52 program office did not have an approved management plan to address DMSMS issues or a complete list of B-52 spare parts. This, in turn, caused the B-52 fleet to not meet its aircraft availability requirements and also caused an increase in obtaining spare parts by cannibalization.

In addition to making recommendations to the B-52 system program office to solve the issue, the report mentions that the $48.6 billion modernization comprise 12 separate modernization programs. Many of them were redacted, however among the unredacted ones there are the already known Commercial Engine Replacement Program, a Tactical Data Link modernization program, the Advanced Targeting Pod Smart Display Sustainment modernization to replace the legacy B-52 Multi‑Function Color Display and the 1760 Internal Weapons Bay Upgrade modernization program intends to allow the B-52 to store up to eight advanced precision-guided Joint Direct Attack Munitions in its internal weapons bay.

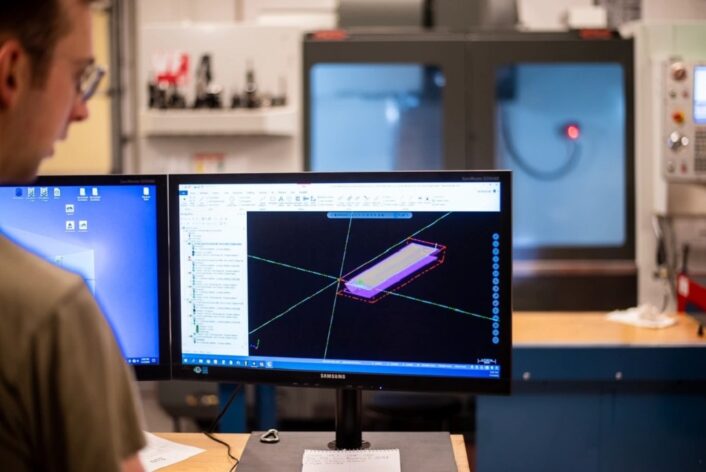

It is worth noting that the shortage of spare parts is a common problem for old aircraft across the service. For an instance, average age of the F-15C Eagles in service is about 38 years old, and many of the aircraft’s spare parts are no longer produced. Because of this, metals technology shops are used to fabricate parts in-house. For example, the shop at Portland Air National Guard Base saved $1.2 million in Air Force Repair Enhancement Program (AFREP) funds in fiscal year 2023 alone by fixing and fabricating various parts for the F-15.