The Solid Fuel Ramjet (SFRJ) and the Hypersonic Dual-Mode Ramjet (DMRJ) are seeing rapid success as the U.S. hikes spending and development of hypersonic weapons.

GE Aerospace has shed more light on its hypersonic propulsion programs, announcing on Sep. 22, 2025 the testing of a Solid Fuel Ramjet (SFRJ) propulsion system and a dual-mode rotation-detonation combustion ramjet at the Kennedy Space Center and the GE Aerospace Research Center in New York, respectively. The SFRJ was installed on the Atmospheric Test Launched Airbreathing System (ATLAS) Flight Test Vehicle that underwent “a successful supersonic captive carry” flight test.

In a promotional video released on Oct. 1, 2025, GE revealed the technical efforts and test parameters of the ATLAS trial on an F-104 Starfighter of Starfighters International, based at KSC, which by Sep. 22 had been put through three successful flight tests. ATLAS, attached as a fixed test article on the port (left)-side wing of the Starfighter – that reached supersonic speeds in the tests, “was funded by the Department of War via Title III of the Defense Production Act to scale up the technology for air-breathing propulsion to extend the range of munitions.”

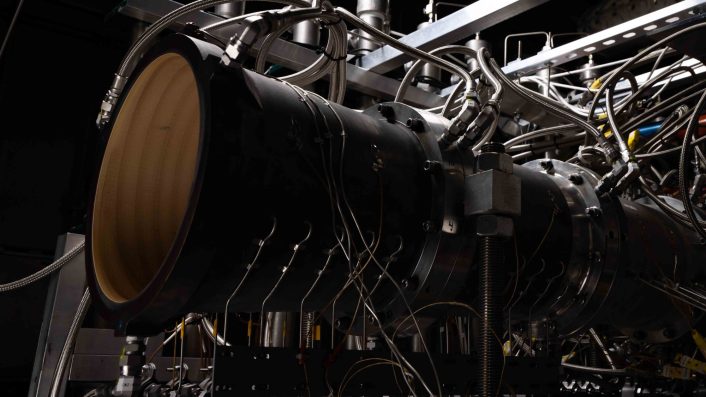

The rotation-detonation engine, called the Hypersonic Dual-Mode Ramjet (DMRJ), was demonstrated by GE for the first time in late 2023 at its research center in Niksayuna in New York. The DMRJ “harnesses rotating detonation combustion (RDC) technology within a supersonic flow stream,” GE said in a Jan. 13, 2025, press release.

🚀 Breaking New Ground in Supersonic Flight!

Carried by a Starfighters F-104 aircraft, last week GE Aerospace announced it has successfully completed supersonic captive carry flight tests of its ATLAS Flight Test Vehicle, marking a major milestone in advancing solid fuel ramjet… pic.twitter.com/TGIZXUhA1I

— GE Aerospace (@GE_Aerospace) September 30, 2025

Solid Fuel Ramjet

The choice of the F-104 Starfighter was owing to its high-speed, that matches the kinematics at which the ramjet engine is expected to begin producing the required output, which could not be reached by other test platforms. Mark Rettig, vice president and general manager at GE Aerospace’s Edison Works Advanced Programs said in the video: “ATLAS is a test vehicle and we are using that to demonstrate in flight relevant conditions our solid fuel ramjet. The F-104 Starfighter can get up to Mach 2.2 and that’s a pretty good speed to demonstrate ignition and sustainment of our SFR.”

The F-104 Starfighter belongs to Starfighters, a company that operates seven such aircraft, offering airborne captive carry testing of up to Mach 2 and for launching payloads from 45,000 feet into space. The graduation from a lab environment, then a ground test environment and finally a flight relevant environment was the “next logical step before we actually fly the vehicle on its own.”

“It gives us enough confidence in the propulsion system to move on to that next phase,” Rettig added. The mention of Mach 2.2 also gives an idea of the flight profile and launch sequence the carrier aircraft is required to achieve, in order to obtain the required airflow for SFRJ engines to ignite and begin producing thrust.

A basic advantage of solid fuel ramjet is that the air-breathing engine provides a continuous thrust, which could also be throttleable, allowing the missile to change directions and maneuver, avoiding conventional trajectory-predicting air-defense missiles. A solid instead of a liquid fuel also reduced overall weight, adding to the high-kinematic endgame characteristics.

🚨 HUGE NEWS 🚨

This week, we announced multiple major milestones that highlight our proven ability to scale advanced propulsion concepts from the lab to real-world testing.

✈️ At Kennedy Space Center, we flew our solid fuel ramjet for the first time in supersonic captive carry… pic.twitter.com/nDisaCySSs

— GE Aerospace (@GE_Aerospace) September 22, 2025

Unlike turbojets or turbofans that use moving components, turbines and compressors, ramjets have specialized air inlets that compress the air to just the right pressure, increase the temperature, ignite the fuel and finally generate thrust.

GE’s dual-mode Rotation Detonation Combustion Ramjet

GE began testing the DMRJ in March 2024 at its facility in Everdale, Ohio, where they used an additively manufactured DMRJ. The company recorded a “three-fold increase in airflow,” making it a “tremendous success, both from a combustion performance and thermal structure perspective.” The 3D-printed engine was designed and built in eight and a half months, while achieving “first fire within 11 months.”

Rotation detonation engines use the ‘detonation’ (and not ‘combustion’ or ‘deflagration’) of fuel, following its mixture with compressed air, as thrust. This allows more thrust with the same amount of fuel, using the detonation’s shockwaves which travel in a circular pathway, with fuel and oxidizers added periodically.

An RDE exploits the powerful detonation shockwave instead of letting it travel out of the longer exhaust tube. Fuel and oxidizers are added into the circular channel through small holes, whose mix causes a detonation. The circling detonation shockwave hits and ignites (or ‘detonates’) another fuel and oxidizer mix, and the cycle continues.

Projects the engines will power

The engines being developed by GE Aerospace do not appear to be poised to power any of the present air-to-ground hypersonic missiles being pursued by the U.S. military, both under-development and flying examples. Aviation Week reported that GE would offer the DMRJ to power DARPA’s Next-Generation Responsive Strike (NextRS) demonstrator, quoting the executive director of the Edison Works division Craig Young.

The NextRS program is focused on developing a new class of long-range strike capabilities that are both survivable and rapidly deployable. The effort aims to produce an advanced platform with increased range, speed, and mission flexibility compared to current ones.

NextRS seeks to enable U.S. forces to penetrate contested environments and deliver precision effects against time-sensitive targets. To achieve the goal, the program will advance new technologies for structures and materials, high-speed weapon separation, dual-mode propulsion, power generation, thermal management systems, and a high-Mach turbine engine.