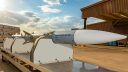

The three weapons of the Barracuda family are optimized for affordable, hyper-scale production, says Anduril, and appears to match the details of the Enterprise Test Vehicles program.

Anduril industries has unveiled, on Sep. 12, 2024, a new family of air-breathing, software-defined expendable Autonomous Air Vehicles (AAVs), called Barracuda, which the company says is optimized for affordable, hyper-scale production. The family consists of three core models: Barracuda-100, Barracuda-250, and Barracuda-500.

Each increment offers increasing size, range and payload capacity, but all Barracudas are compatible with a host of payloads and employment mechanisms, support a variety of different missions, and provide warfighters with an adaptable and upgradeable capability to counter evolving threats, said Anduril.

“Barracuda-M is the munition configuration of Barracuda that delivers a more affordable, producible, available, and adaptable cruise missile capability than existing options available to warfighters today,” says the press release. “The Barracuda family of AAVs is designed to rebuild America’s arsenal of air-breathing precision-guided munitions and air vehicles.”

The press release, similarly to other recent programs, reflects on the fact that the United States need a high volume of munitions to be ready for a possible conflict with a near-peer adversary.

“The United States and our allies and partners do not have enough missiles to credibly deter conflict with a near-peer adversary,” says Anduril. “Our existing arsenals of precision-guided munitions would be exhausted in a matter of days in a high-end fight.”

The Barracuda-M

Anduril provided a brief description for each of the three models.

“Barracuda-100 packs high performance into a small, modular form factor that unlocks new ground or air-launched concepts of operation for tactical forces,” said the caption. The weapon has a payload of 35 lb and a range of over 85 miles in the air-launched variant.

Among the expected platforms are the AH-1Z and AH-64 helicopters and the C-130 family. The image shows the weapon equipped with what could be an Electro-Optical sensor in the front.

Barracuda-250 is described as a low-cost AAV designed for flexible employment from a variety of air, ground, or maritime platforms, including the internal weapons bays of fifth-generation fighter aircraft. Anduril says it is optimized for operational utility across the joint force, supporting multiple payloads, platforms, and concepts of operation.

Similarly to the smaller Barracuda-100, the weapon is reported to have a 35 lb payload but a much greater range, which is over 200 miles if air-launched. Among the expected platforms are the F-35 and bombers for internal carriage, as well as F-15, F-16 and F/A-18 for external carry.

The largest variant, the Barracuda-500, is described as an affordable long-range mission system capable of mass production, load-out, and deployment. With 500+ nm range and 100+ lb payload capacity, Anduril says Barracuda-500 can be air-launched en masse to deliver a variety of effects for extended range missions.

Interestingly, among the expected platforms, Anduril did not only list the F-15, F-16 and F/A-18, but also palletized systems such as Rapid Dragon on the C-130 and C-17. This could imply a size similar to the AGM-158 JASSM already tested with Rapid Dragon.

Anduril also mentions the weapons being able to maneuver at 5 Gs and loiter for 120 minutes. The Barracuda family is propelled by a turbojet engine, which allows an unspecified high speed.

‘Affordable hyper-scale production’

According to the company, “a single Barracuda takes 50 percent less time to produce, requires 95 percent fewer tools, and 50 percent fewer parts than competing solutions on the market today”. This follows a previous mention of existing missile designs being “highly complex, require thousands of unique tools to produce, demand highly-specialized labor and materials, and are built on the backs of tenuous, brittle, and defense-specific supply chains.”

The reach that objective, Anduril says Barracuda leverages commercially and widely-available components across six common sub-systems and minimized unique tooling and part count to accelerate assembly and ensures flexibility. The weapon is also described as a software-defined, hardware-enabled platform based on a modular open systems architecture that can be rapidly upgraded.

Here is also an interesting excerpt from the press release, in which Anduril says the weapon could also be produced by the automotive and electronics industries to meet a surge in demand:

Barracuda is designed to be simple to manufacture, both in terms of tooling and talent. Designed for rapid assembly at low cost, the Barracuda family of AAVs only requires ten or less tools to assemble, ensuring that both new and existing production lines can be rapidly spun up to produce AAVs at hyper-scale. The simplicity of Barracuda’s design and manufacturing process has an additional benefit: Barracuda can be produced by the broad commercial automotive and consumer electronics workforce, rather than relying exclusively on the much smaller, over-stretched, highly-specialized, defense-specific manufacturing labor pool required to produce existing solutions.

To increase the flexibility, the weapons are based on a core made of a handful of common subsystems, with new subsystems easily and rapidly swapped into live production lines. The company also says the commercial off-the-shelf components give the supply chain resiliency, redundancy, and surge capacity.

The Enterprise Test Vehicles effort

The Barracuda might be Anduril’s pitch for the Enterprise Test Vehicles program of the Air Force Armament Directorate and the Defense Innovation Unit. The program is meant to demonstrate modularity for subsystem upgrade testing, as well as serve as foundation for a cheap mass production.

In order to keep the ETVs affordable, commercial off-the-shelf (COTS) components are being used wherever possible. The competitors will also leverage modern design for manufacturing approaches, ensuring air vehicles are not over-engineered for their intended mission, minimize use of expensive materials, and enable on-call high-rate production that is not possible with more exquisite counterparts.

Both DIU and the Air Force requested to maximize the use of COTS components to keep the cost low. In fact, the cost goal for bulk order of the system once in full-rate production is $ 150,000 per unit, much lower than the price of a “classic” cruise missile such as the AGM-158 JASSM or the Joint Strike Missile whose prices are in excess of one million dollars.

Previously, DIU also said that the ETV should have a range of 500 nm (926 km) and also be able to deliver a kinetic payload at highly subsonic speed. All the details disclosed so far for the ETV program appear to match the info released by Anduril about Barracuda, with the range details matching specifically the Barracuda-500.